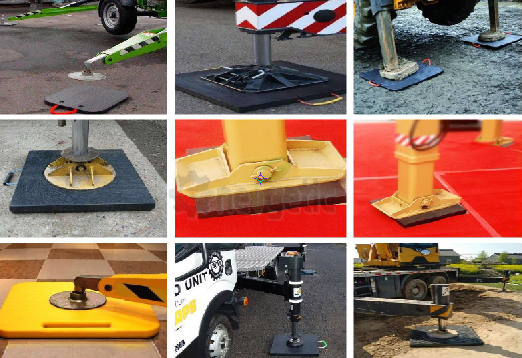

Outrigger Pads can provide more stable support force for large construction machinery such as Laders, wheel cranes, excavators and concrete machines. The Outrigger Pads saves the use cost and improves the work quality.

Material Selection of ENERGEITC Outrigger Pads:

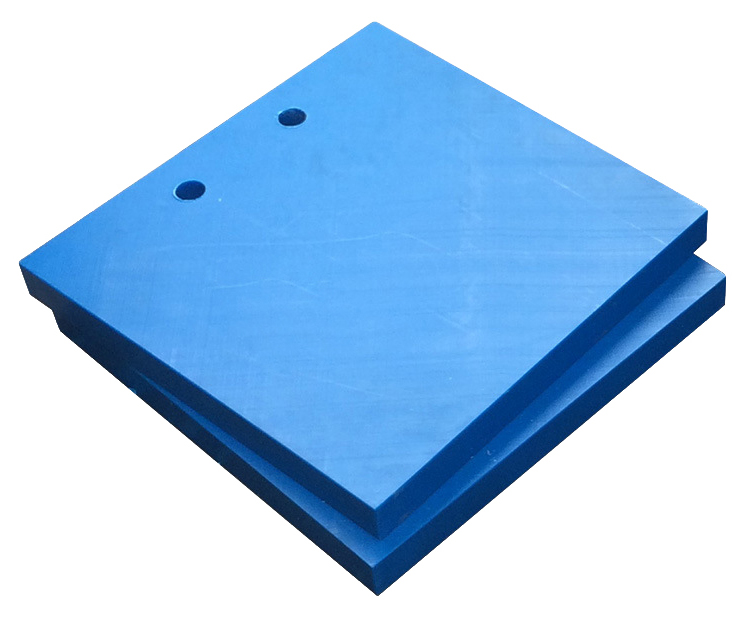

ENERGEITC use Ultra-high molecular weight polyethylene (UHMWPE) to make Outrigger Pads. Compared with other plastics, UHMWPE gives following excellent properties:

1. The impact strength of UHMWPE sheet is very high, 10 times higher than that of nylon and polypropylene (PP).

2. The abrasion resistance of UHMWPE sheet is very excellent. The abrasion test of mortar shows that the abrasion resistance of UHMWPE sheet is several times higher than that of common carbon steel and copper, and 4-5 times higher than that of nylon and PTFE, which ranks in the forefront of existing plastics.

3. The friction coefficient of UHMWPE liner is very low, and its dynamic friction coefficient is 0.07-0.10, which is comparable to that of PTFE. It is an ideal self-lubricating material.

4. Polymer polyethylene sheet can absorb shock and prevent noise.

5. Polyethylene sheet is resistant to chemical corrosion and can shield atomic radiation. In a certain temperature and concentration range, many corrosive media (acid, alkali, salt) and organic solvents and other corrosive media also have no alternative to it.

6. Ultra high molecular polyethylene sheets are not easy to adhere to foreign bodies and have excellent anti-adhesion properties when sliding.

7. tasteless, non-toxic, odorless, non-polluting and non-corrosive. The Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) allow it to be used in direct contact with food and medicines. Therefore, it is suitable for industries requiring high hygienic conditions such as food and medicine. It can be recycled. Compared with other plastics, it has good thermal stability and non-water absorption. The size of the product will not change because of water absorption in humid environment, and it will not affect the accuracy and wear resistance of the product. The raw material does not need to be dried before forming.

8. The working temperature range can be from - 200 to + 100 and from low temperature to - 195 it can still maintain good toughness and strength without brittle cracking.

ENERGETIC Outrigger Pads Production:

As for the production of special Outrigger Pads for engineering vehicles, we can produce according to customers' drawings and samples. Products can be processed according to drawings or samples. Drawings can be provided within 12 hours, daily maintenance of Outrigger Pads, and general specification products can be shipped within 7-10 days.

Delivery details can be negotiated, flexible operation, provide pre-sale and after-sales service, we have a professional production team, independent technology department and laboratory, strict quality control, market price of Outrigger Pads, we will strive to achieve high-quality products, high-quality service, welcome new and old customers to call for advice.

Our company is the largest production base of high molecular polyethylene leg cushion in China, and a professional manufacturer of polyethylene industry in China. The quality and price of the polyethylene leg cushion plate produced by the company have been recognized by the majority of users.

We solemnly promise that the outrigger cushion plate, which is a rather bent and continuous plate, can be used for 5-10 years in the normal weighing range. In recent years, this new type of polyethylene cushion plate has been widely used in construction machinery vehicles all over the country.

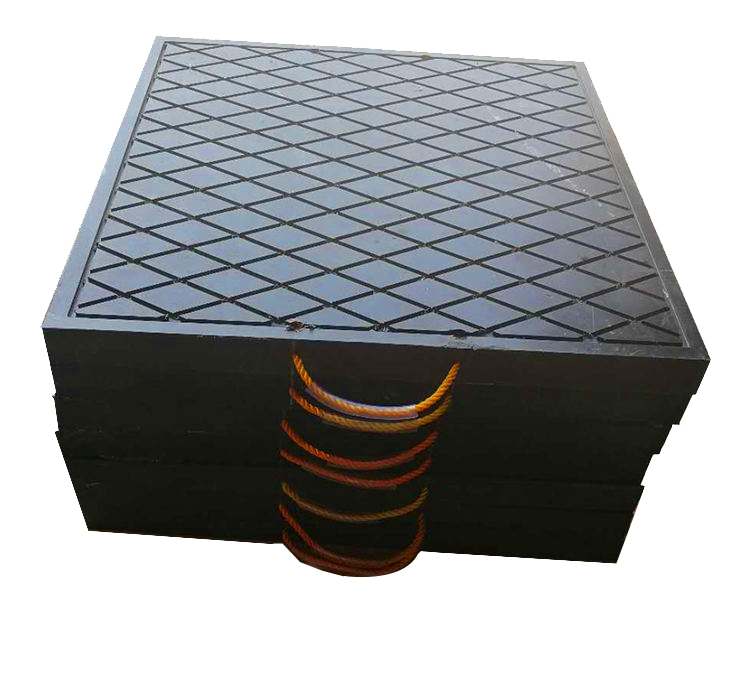

ENERGETIC Outrigger Pads Instructure:

The outrigger pad is composed of two parts, the plate-shaped pad body and the portable rope. The plate-like cushion body is pressed by UHMW polymer composite material. Polymer PE synthetic material cushion plate four corners support, 60 mm bearing pressure 15-18 tons/cm above, can be used in harsh environment, use rather bend but not break.

The portable rope is made of nylon material, and the end of the portable rope is embedded in the body of the cushion plate for easy transportation and layout.

Outrigger Pads is the pad under the legs of construction machinery, can effectively distribute the weight and lifting weight of construction machinery to the area of outrigger pads to ensure the safety of the ground working environment of construction machinery.

When the working environment of construction machinery on the ground is not sure whether it is good or not, the use of our leg cushion can effectively avoid bad occurrence. The Outrigger Pads is mainly used under the support legs of construction machinery, and plays a supporting role. The outrigger cushion plate has high strength and stiffness.

Contact: Eva Jiang

Phone: +86 189 3326 4608

Tel: +86-755-89664362

Email: sales@energetic-industry.com

Add: No.601-11, Anbo Technology Baolong Industrial Zone, Baolong 4th Road, Longgang District, Shenzhen, China