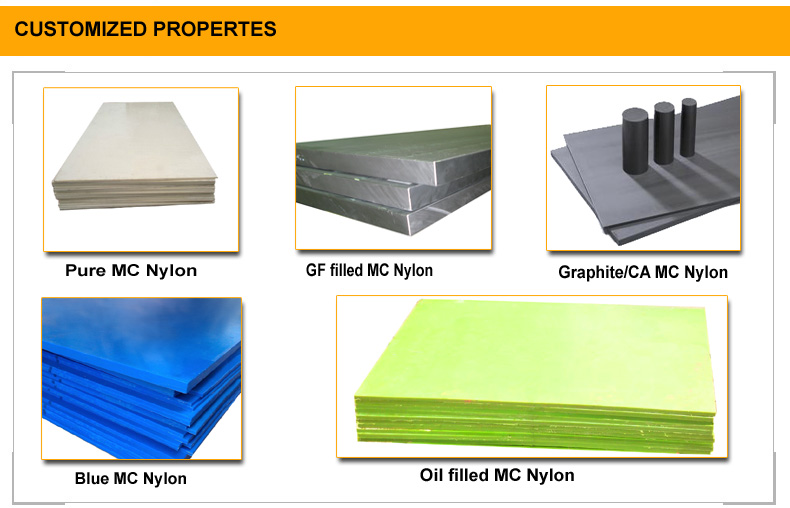

Excepted pure semi-finished plastic material, we also can custom plastic properties according to client's request.

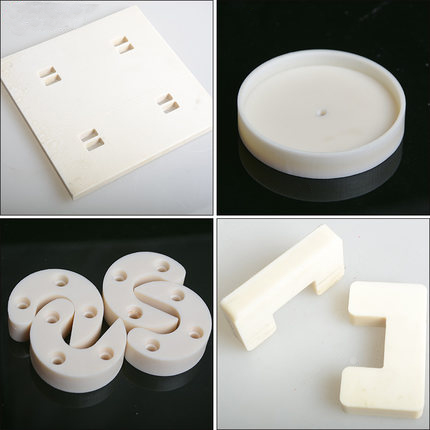

- Support cut as request size, machined into parts

|

Materials Available |

General Plastic: HDPE, PP, PVC, ABS, PMMA(Acrylic) ect. |

|

Engineering Plastic: POM, PA6, MC nylon, Nylon 66, PTFE, UHMWPE, PVDF ect. |

|

|

High Performance Plastic: PPS, PEEK, PI, PEI ect. |

|

|

Thermosetting Plastic: Durostone, Ricocel sheet, G10, FR4, Bakelite ect. |

|

|

Spcial Plastic Material: Plastic+GF/CA/Oil/Brone/Graphit/MSO2/ceramic ect. |

|

|

Spcial Plastic Plastic Alloy: PE+PA, PP+PA, POM + PTFE ect. |

|

|

Special parts: Metal + Plastic Combined Part |

MC Nylon, Conductive Nylon, ESD Nylon, MC Nylon 6 + oil filled (PA6 + oil) - green, Nylon 6 + MOS2 (PA6 + MoS²) – grey black, Nylon 6+ GF30 (PA 6-GF30) - black, Nylon 66

About MC Nylon:

Unmodified cast nylon 6 grade exhibiting characteristics which come very close to those of nylon 66. It combines high strength, stiffness and hardness with good creep and wear resistance, heat ageing properties and machinability.

Advantages:

MC nylon are more tough, durable than extruded nylon 6, also general purpose engineering material with special grades for specialty applications. Typical application conditions would be medium speed and temperature in a rugged, abrasive, impact and high load environment.

Disadvantages:

Poor dimension stability, electrical and mechanical properties, may become affected by absorbing moisture or water, acid proof ability not good, can’t dye with acid or touch overmuch acid, weak light fastness, low endurance in pollution.

Key Features:

▪ Excellent bearing properties

▪ High impact strength and toughness

▪ Low power factor requirements

▪ High wear resistance

▪ Very good sliding properties

Applications:

▪ High load bearings

▪ Wear pads

▪ Support and Guide wheels

▪ Conveyor and Tension rollers

▪ Wire rope sheaves

▪ Buffer pads

▪ Gears, etc.

Nylon Products:

▪ Extruded Nylon 6 (PA 6) - natural (white) / black:

Offers an optimal combination of mechanical strength, stiffness, toughness, mechanical damping properties and wear resistance. These properties, together with a favourable electrical insulating ability and a good chemical resistance make extruded nylon6a"general purpose" grade for mechanical construction and maintenance.

▪ MC Nylon 6 (PA 6) - natural (ivory) / black:

Unmodified cast nylon 6 grade exhibiting characteristics which come very close to those of nylon 66. It combines high strength, stiffness and hardness with good creep and wear resistance, heat ageing properties and machinability.

▪ MC Nylon 6 + oil filled (PA6 + oil) - green:

This internally lubricated cast nylon 6 is self-lubricating in the real meaning of the word. Oil filled MC nylon 6, especially developed for unlubricated, highly loaded and slowly moving parts applications, yields a considerable enlargement of the application possibilities of nylons. This because of its reduced coefficient of friction (up to -50%) and improved wear resistance (up to x 10).

▪ Nylon 6 + MOS2 (PA6 + MoS²) – grey black:

The addition of MoS² renders this material somewhat stiffer, harder and dimensionally more stable than nylon 66, but results in some loss of impact strength. The nucleating effect of the molybdenum disulphide results into an improved crystalline structure enhancing bearing and wear properties.

▪ Nylon 6+ GF30 (PA 6-GF30) - black:

when compared with virgin nylon 6, this 30% glass fibre reinforced and heat stabilised nylon grade offers increased strength, stiffness, creep resistance and dimensional stability whilst retaining an excellent wear resistance. It also allows higher max. service temperatures.

▪ Nylon 66: this material with a higher mechanical strength, stiffness, heat and wear resistance than extruded nylon 6. It also has a better creep resistance but its impact strength and mechanical damping ability are reduced. Well suited for machining on automatic lathes.

Contact: Eva Jiang

Phone: +86 189 3326 4608

Tel: +86-755-89664362

Email: sales@energetic-industry.com

Add: No.601-11, Anbo Technology Baolong Industrial Zone, Baolong 4th Road, Longgang District, Shenzhen, China