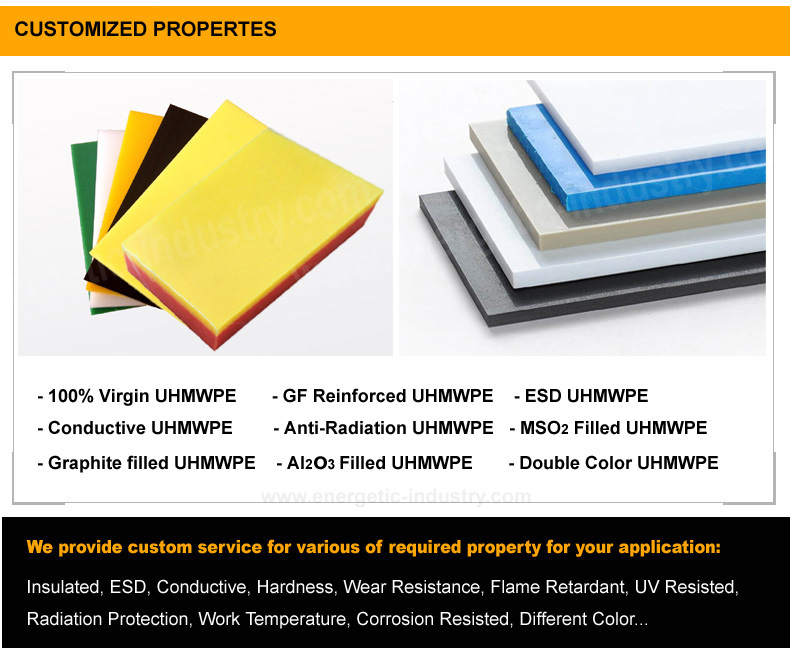

Types Included:

Molded UHMWPE, Conductive UHMWPE, ESD UHMWPE

About UHMWPE:

UHMWPE (also known as Ultra High Molecular Weight Polyethylene) Sheet and Rod products are manufactured from the semi-crystalline polyethylene (PE) family. Chinese UHMWPE Sheet and rods’ maximum molecular weight can reach to 5 million which has a positive impact on material performance in an abrasive environment.

UHMWPE Advantages:

UHMWPE properties ensure that this plastic material is very light, extremely tough, chemically resistant and has excellent wear resistance.

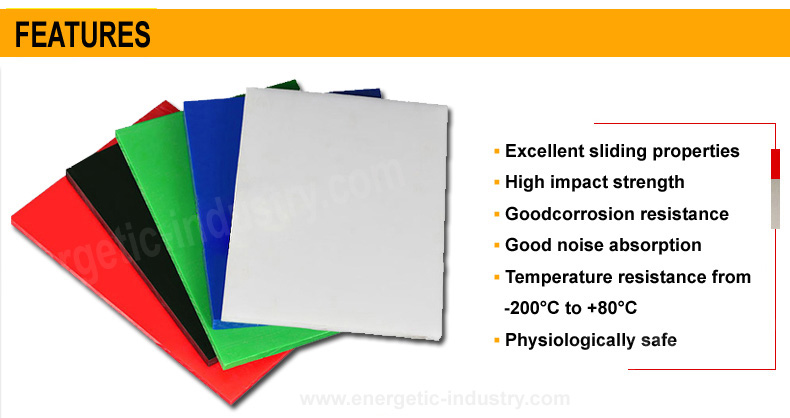

Key Features:

▪ Excellent sliding properties

▪ High wear resistance

▪ High impact strength

▪ Very good chemical and corrosion resistance

▪ Good noise absorption

▪ Anti-adhesive

▪ High energy absorption capacity and high stress rates

▪ Temperature resistance from -200°C to +80°C

▪ Physiologically safe

Applications:

▪ Chemical Engineering: Corrosion and wear resistance mechanical parts

▪ Thermal power: coal handling, storage of coal, warehousing chute lining

▪ Coal processing: sieve plate, filter, U-underground coal chute

▪ Concrete: cement raw and finished product silo lining

▪ Grain: food storage or chute lining

▪ Mining: sieve plate, chute linings, wear anti-bonding part

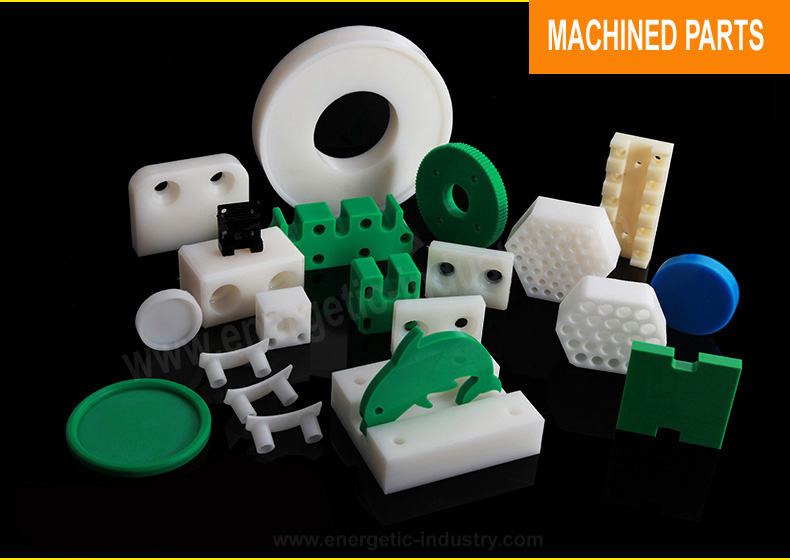

▪ Food industry: star-shaped wheel, transmission timing bottle screw, bearings, guide rollers, guides, slide blocks, etc.

UHMWPE Products:

▪ Extruded or Molded UHMWPE:

Unfilled, natural white

▪ ESD UHMWPE:

ESD/Anti-static properties of PE-UHMW are often required with high line speeds and conveying rates. ESD UHMWPE meets these requirements. Anti-static properties are achieved by incorporating efficient carbon black types.

Contact: Eva Jiang

Phone: +86 189 3326 4608

Tel: +86-755-89664362

Email: sales@energetic-industry.com

Add: No.601-11, Anbo Technology Baolong Industrial Zone, Baolong 4th Road, Longgang District, Shenzhen, China